Roof edge block 600x390x100mm

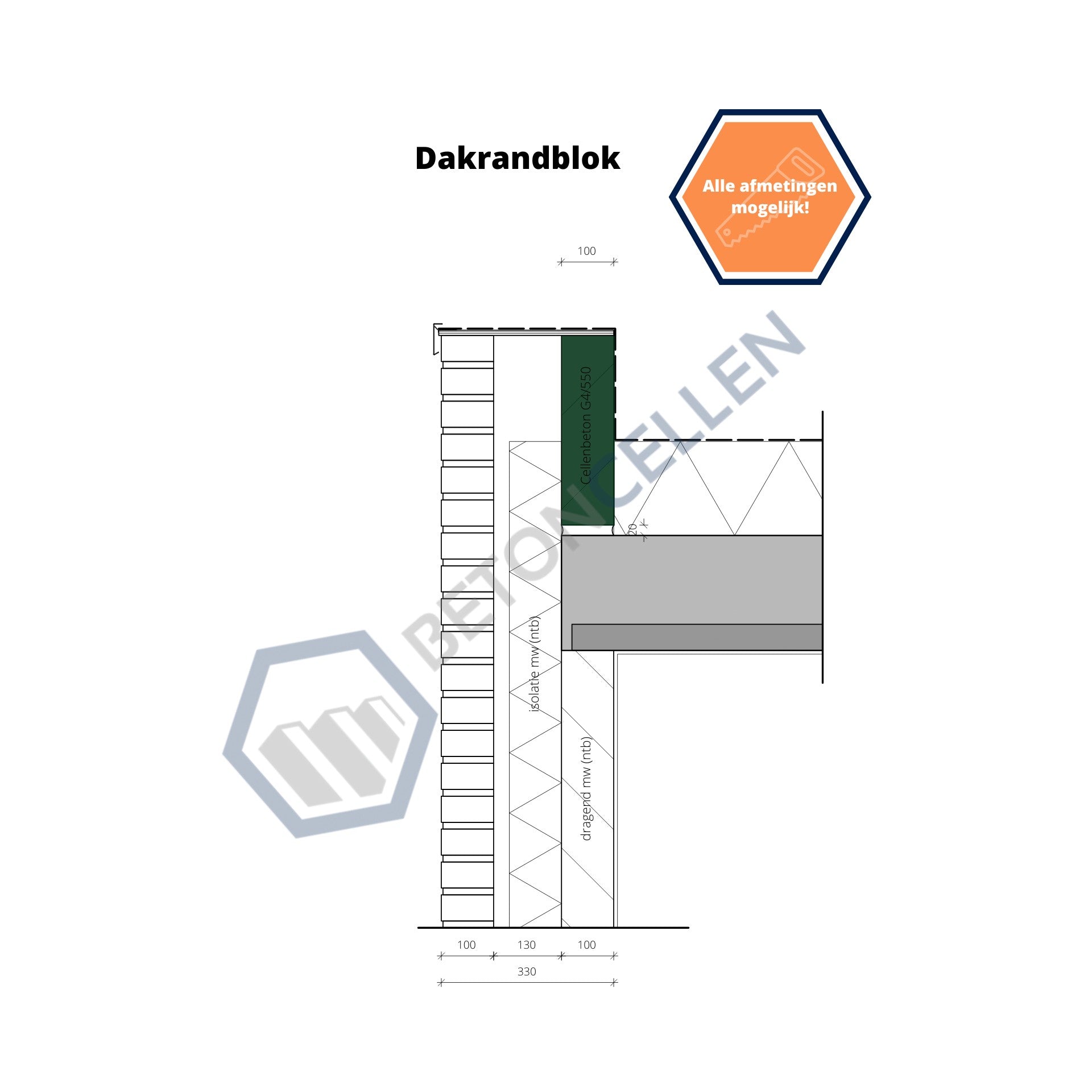

Building with the Aerated Concrete Roof Curb offers efficiency and time savings. These roof edge blocks can be placed directly, so that the correct height is immediately achieved. This eliminates the need to cut the blocks to size on site, resulting in savings in labor costs and time. After placing these ready-made roof edges, the blocks can be finished immediately.

The roof edge blocks are placed on the rough concrete floor. Because this floor is not always completely flat, the blocks are placed in a bilge layer mortar of at least 15 mm thickness to ensure that this layer is always flat and level. To seal the gap between the inner and outer walls, a plywood sheet is placed on the outer wall and the aerated concrete eaves block and fixed with screws and plugs.

As an extra service, the roof edge blocks can be provided with an adhesive primer on the underside. This primer ensures optimal adhesion of the mortar and the aerated concrete block. The primer has a green dye to make it clear which side should be in the base layer mortar. This prevents moisture from being extracted from the mortar too quickly, preventing the blocks from becoming loose.

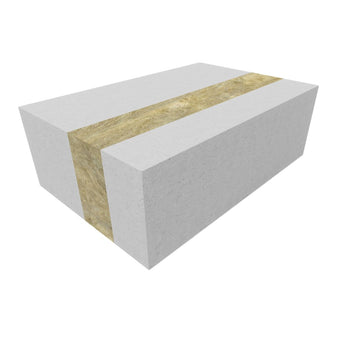

Aerated concrete offers easy processing, which increases construction speed. In addition, it prevents cold bridges and is not sensitive to moisture or mold.